What is SMT Basics ?

SMT basics first priority is cleanliness, in Korea we called – 1st priority is clean, 2nd also clean, 3rd also clean.

Basic is simple and easy, but proves highly significant. Some of you might have worked in the area of SMT for many years. Hence it is no wonder that you feel tempted to skip this basic part. Nevertheless, you cannot and should not go any further deeper level of surface mount technology and management skill unless you get the basics of SMT.

Why does SMT need cleanliness?

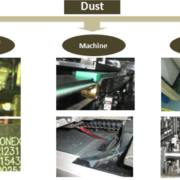

Why does dust draw our big concern?

Because dust creates a lot of problems.

Firstly, dust affects badly on production & quality: leading to component lift-up, missing, tilt, and so on.

Secondly, it causes breakdown of machine: Sensor error, nozzle & filter blockage.

Thirdly and most importantly, it brings about a loose attitude of mind towards untidy line environment. When litter is heaped on a roadside, people are tempted to throw more to them; however, when a place is spotlessly clean, people certainly carry a burden to throw rubbish.

Hence, in SMT 1st, 2nd & 3rd is required to be clean.

Comment on above post – consulting@ybtechsoluiton.com