What is LCR Check? Why it is Important?

/in SMT News /by ybtechsolution@gmail.comThe process of measurement of component value mounted by Pick & Place machis is called LCR check.

In SMT LCR check is one of the basic process for program validation & loading check.

LCR check is done to validate the new product program or verify the running model material loading (In Pick & Place m/c).

The operator or quality inspector compares the measured value of component placed by Pick & Place m/c on Printed circuit board with the help of LCR meter and compare it with Bill Of Material (BOM).

This process ensures that the program made by programmer is correct or not. It also verifies the component spool is loaded correctly on its respective location or not.

Alot of companies skip this process. The reason of skip is due to lengthy process and unawareness of its importance.

Manual Insert line case even though have human mistake it will affect on 1 or 2 PCBs only but in SMT case if any mistake did it will affect on 1 spool component qty. (3,000 to 10,000)

Few companies follow this process but not have monitoring system. Operator himself measures the value and record it the sheet, sometimes not make any record also. In this case you cannot control human mistakes.

To avoid such incidents here we would like to introduce program based LCR measurement system “ProLCR System”

By this system you can reduce the LCR checking time & avoid human mistakes.

It can be used for traceability & avoid quality skips in process to ensure customer product reliability.

The frequency of LCR checking is at the time of changeover (First Part Approval) or at new product development.

You can use this system for traceability as the LCR measurement result is saved in Database (No need to make hand written report).

Quick & reliable measurement system.

Displays the measurement path on screen & avoid Human mistakes.

Auto compare the measured value of Resistor, Capacitor & Inductor with BOM.

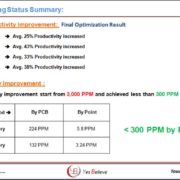

Our customers achieved Quality below 300PPM (By PCB)

/in SMT News, Technical update /by ybtechsolution@gmail.comOur customers have achieved Quality level below 300PPM by PCB and below 10 PPM by Point.

Why Need SMT Training Solutions?

/in SMT News, Technical update /by ybtechsolution@gmail.comRecently we observed the manpower shortage in SMT sector at Pune area. Several companies are now hiring but due to manpower shortage the salary demand by experienced manpower has been increased drastically. The persons with 7~8 years experience are demanding for double salary as compare to what they were getting 2 years back.

This is a dangerous situation for manufacturer.

Korea & China also faced same situation but they got SMT consulting and training from other country that’s the reason this situation not affected a lot on their salary as they quickly improved manpower skill. But at India situation is something different, here manufacturers are not ready to spend money for consulting and training because they worried after training trained manpower will leave the company. Other difference is at Korea, we don’t like to pickup a person who frequently change their jobs because we can’t guarantee when they’ll leave. But what I observed here, the person having more companies experience will get higher salary. I have seen within 1 year a person have changed 3 companies and doubled his salary. This is due to manpower shortage. If a company wants a skilled manpower they need to increase his salary but how can you verify his skill and know-how?

At present the skill is verified by the previous company’s Name and Salary. It means the person having big company experience & higher salary are preferred. There is no procedure to verify the skill of a person who is interviewing the candidate. If he doesn’t have enough knowledge then How he will select a skilled manpower?

Here the main problem is without improving the skill, only salary is getting increased. If skill also improved with salary then there is no issue because Productivity & Quality will also improved simultaneously.

2 years back I had explained, exactly same situation in my seminar. It is a beginning, when more SMT manufacturing plants will open, the manpower demand will be higher.

In this situation while India strives towards Make in India, increasing labour costs threaten to erode India’s advantage in producing goods and services at low cost. The foreign investors are shifting from China to India due to high salary demand at China. If the situation will be same at India, for them it will be difficult to survive here too.

The only solution I can see for this situation is conducting Training Programs to upgrade the skill of SMT manpower and providing Process Consulting to make correct procedures at manufacturing plants.

We are

YB Techsolution Pvt. Ltd.

Addr:

204, Second Floor, Turning Point Bldg-2, Opp. Rosary School, Above Irani Cafe, Viman Nagar,

Pune-411014(MH), India.

Contact No.: 8999778454

Opening Hours

Mo-Sa: 9:00-17:00