What is LCR Check? Why it is Important?

The process of measurement of component value mounted by Pick & Place machis is called LCR check.

In SMT LCR check is one of the basic process for program validation & loading check.

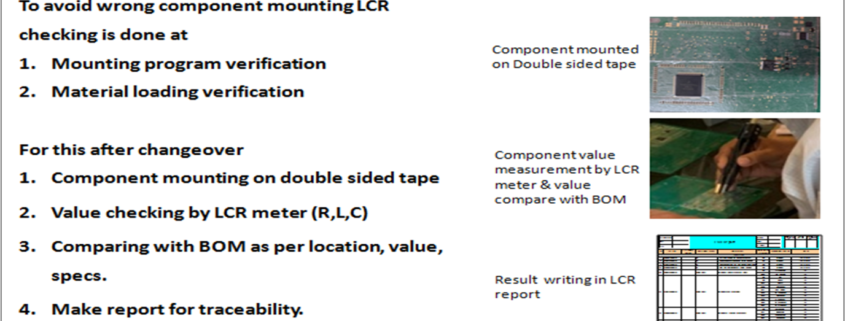

LCR check is done to validate the new product program or verify the running model material loading (In Pick & Place m/c).

The operator or quality inspector compares the measured value of component placed by Pick & Place m/c on Printed circuit board with the help of LCR meter and compare it with Bill Of Material (BOM).

This process ensures that the program made by programmer is correct or not. It also verifies the component spool is loaded correctly on its respective location or not.

Alot of companies skip this process. The reason of skip is due to lengthy process and unawareness of its importance.

Manual Insert line case even though have human mistake it will affect on 1 or 2 PCBs only but in SMT case if any mistake did it will affect on 1 spool component qty. (3,000 to 10,000)

Few companies follow this process but not have monitoring system. Operator himself measures the value and record it the sheet, sometimes not make any record also. In this case you cannot control human mistakes.

To avoid such incidents here we would like to introduce program based LCR measurement system “ProLCR System”

By this system you can reduce the LCR checking time & avoid human mistakes.

It can be used for traceability & avoid quality skips in process to ensure customer product reliability.

The frequency of LCR checking is at the time of changeover (First Part Approval) or at new product development.

You can use this system for traceability as the LCR measurement result is saved in Database (No need to make hand written report).

Quick & reliable measurement system.

Displays the measurement path on screen & avoid Human mistakes.

Auto compare the measured value of Resistor, Capacitor & Inductor with BOM.